[Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT]

Our Selling Price: US$123.20 [Regular Price: US$176.00]

Item Description

DAEMON D32 Spool Conversion Kit

For ABU Ambassadeur 1500C/2500C

| Features

- Enlarged spool diameter helps reduce rotation speed during casting

- Increased spool diameter boosts maximum retrieve length

| Product Overview

This kit upgrades your existing φ30mm spool for the 1500C/2500C to φ32mm.

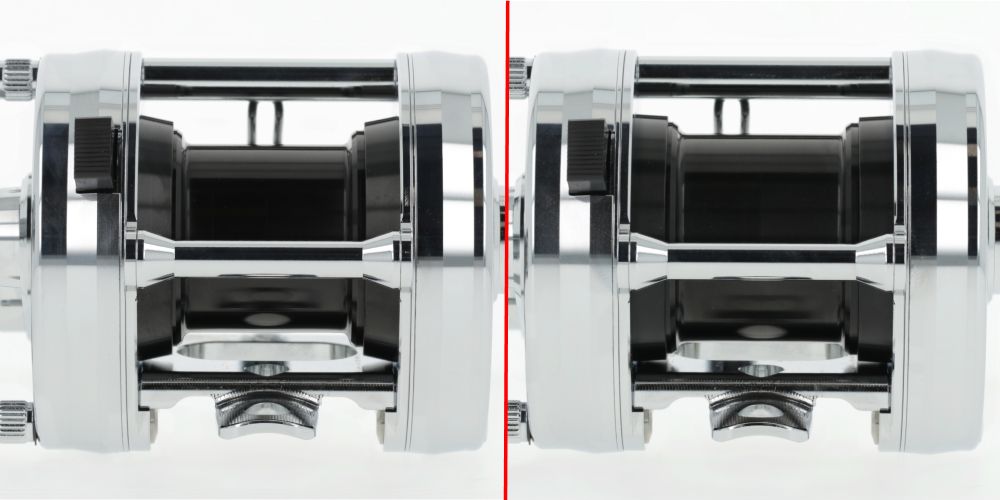

Left: Microcast Spool AMB2520R Right: Microcast Spool D32 AMB2516R

- Enlarged Spool Diameter Reduces Rotation Speed

By increasing the diameter from the genuine φ30mm to φ32mm, this spool reduces rotation speed during casting and minimizes braking resistance. The wider brake adjustment range helps improve casting distance.

- Increased Diameter for Higher Retrieve

Approx. 6.7% increase in max retrieve length (theoretical value)

| Type

DAEMON D32 Spool Conversion Kit 1500C

DMN-D32KIT-1500

4580498105778

DAEMON D32 Spool Conversion Kit 2500C

DMN-D32KIT-2500

4580498105761

| Set Contents

| DAEMON D32 Spool Conversion Kit | Microcast Spool D32 AMB2516R Microcast Spool D32 AMB1516R |

1 piece (either type) |

| Brake Plate Ring φ32 | 2 pieces |

* Reel body not included. Please transplant the side cup and internal parts.

| Specifications

| Spool Dimensions (Diameter / Groove Depth) | |

| Microcast Spool D32 AMB2516R Microcast Spool D32 AMB1516R |

φ32mm / Groove Depth 1.6mm |

| Material | |

| Spool Body | Extra Super Duralumin |

| Spool Shaft | Extra Super Duralumin |

| Brake Plate Ring φ32 | Extra Super Duralumin |

| Spool Bearing Size | |

| Outer Dia. 11mm × Inner Dia. 5mm × Thickness 4mm | |

| Weight | |

| Microcast Spool D32 AMB2516R Microcast Spool D32 AMB1516R |

Approx. 5.7g Approx. 5.2g |

| Brake Plate Ring φ32 | Approx. 5.3g (per piece) |

| Line Capacity *For PE Line Only | |

| Microcast Spool D32 AMB2516R Microcast Spool D32 AMB1516R |

PE 0.4-110m 0.6-75m 0.8-55m PE 0.4-90m 0.6-60m 0.8-45m |

| Compatible Models | |

Compatible with 1500C/2500C reels equipped with Avail Brake Plate (Ver.5 or later) and Avail Palming Plate * Not compatible with genuine components |

|

| Compatible Brake Systems | |

[Centrifugal Brake] Centrifugal Brake for Ambassadeur 2500C "Kaiketsu Porori" 4P Brake Type2 for 2500C * Compatible with B-Block Extra Small only * Not compatible with genuine brake |

|

| How to Install the Brake Plate Ring

Brake plate rings differ between previous Avail models (left) and D32 models (right).

Please make sure you do not confuse them during installation.

Palming Plate Side

1. Remove the two screws with a flathead screwdriver (size 2).

* Be careful not to damage the screws or surrounding parts. Use the correct tool.

* Both screws used on the palming plate are the same size.

2. While holding the D32 brake plate ring with your finger, align the holes and attach it.

* Do not overtighten the screws.

Brake Plate Side

Note that the two screws differ in length.

1. Remove the two screws with a Phillips screwdriver (size 1).

* Be careful not to damage the screws or parts. Use the correct tool.

2. Just like the palming plate side, attach the D32 brake plate ring.

* Do not overtighten the screws.

| How to Install the Spool

Installation is the same as for the Microcast Spool for ABU Ambassadeur 2500C.

Please refer to the video below for replacement instructions.

| Notes

* Genuine brake plates and palming plates are not compatible.

Due to design differences, please be sure to use Avail brake plates (Ver.5 or later) and Avail palming plates.

* Always start with maximum brake setting when casting.

* Microcast spools are thinned to the limit of required strength for weight reduction.

Reel drive noise may echo inside the spool and sound louder, but this does not affect actual use.

* When winding line onto the spool, avoid applying excessive tension to prevent damage.

* When using centrifugal brakes, the brake block will strip the anodized surface inside the brake plate ring.

Until the coating is fully worn off, wear particles may appear and affect bearing performance. Frequent cleaning is recommended.

| Gallery

![Photo1: [Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT] (1)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303235303531365f3963343063352e6a706700363030000074006669745f686569676874.jpg)

![Photo2: [Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT] (2)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303235303531365f3736366331382e6a706700363030000074006669745f686569676874.jpg)

![Photo3: [Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT] (3)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303235303531365f6130343763342e6a706700363030000074006669745f686569676874.jpg)

![Photo4: [Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT] (4)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303235303531365f6135306361312e6a706700363030000074006669745f686569676874.jpg)

![Photo1: [Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT] (1)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303235303531365f3963343063352e6a706700313130000074006669745f686569676874.jpg)

![Photo2: [Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT] (2)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303235303531365f3736366331382e6a706700313130000074006669745f686569676874.jpg)

![Photo3: [Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT] (3)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303235303531365f6130343763342e6a706700313130000074006669745f686569676874.jpg)

![Photo4: [Avail] DAEMON D32 Spool Conversion Kit for ABU Ambassadeur 1500C/2500C [DMN-D32KIT] (4)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303235303531365f6135306361312e6a706700313130000074006669745f686569676874.jpg)