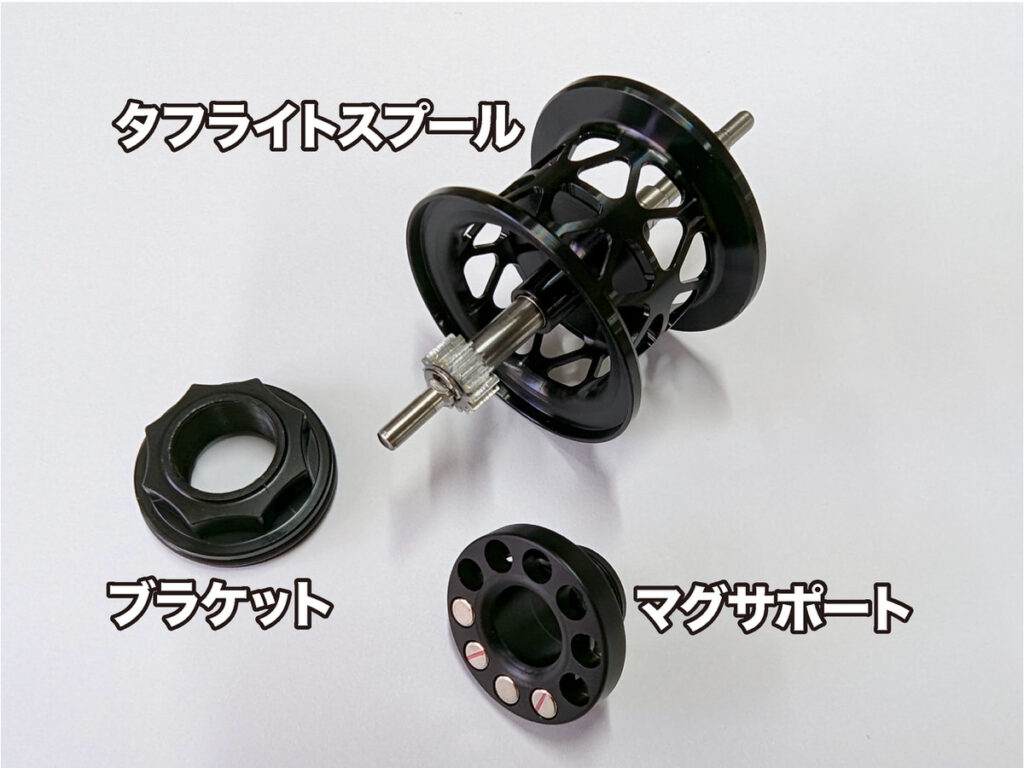

[TRY-ANGLE] Tough Light Spool & Mag Brake System Set

Our Selling Price: US$113.96 [Regular Price: US$162.80]

Prices vary according to options.

Item Description

A must have for all mountain stream bait finesse anglers! Robust and lightweight spools for the BC series are now available!

The long-awaited genuine ISUZU Industry spools for the BC42/52 series are now available for the "finesse spools," which are a must-have custom part for mountain stream bait fishing!

Triangular shaped holes are used to reduce weight by more than 60% from the normal spool.

The lightweight and rigid finish is the result of precise design and repeated testing on a variety of fish species.

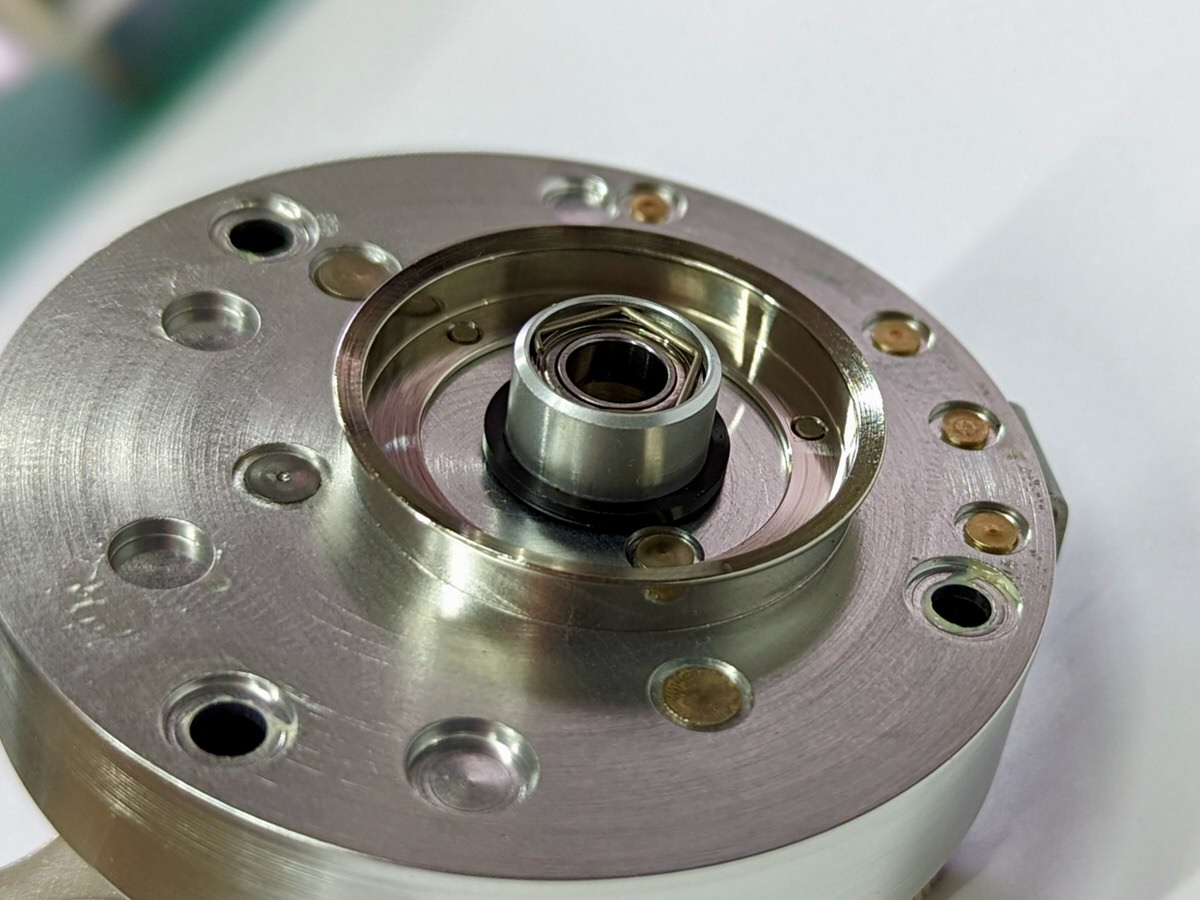

It is also the first genuine part to feature a magnetic brake system.

Because it is a non-contact type, it is extremely less affected by humidity and weather than a centrifugal brake, allowing minnows in the 2g range to be cast consistently and comfortably.

Additional magnets (sold separately) can be installed to further enhance braking effectiveness.

Medium size BC series makes the lure go farther. Higher precision.

Medium shallow spool compatible with medium size reels "BC62/73 series" and "BC72 series" made by ISUZU Industry Inc. and finesse lines.

Triangular-shaped holes provide light weight and high rigidity.

The lightweight spool allows for lighter casts and improved accuracy.

It allows you to approach the point from a more remote location.

In addition, a stainless steel spool shaft is used in this product to handle the fight of large fish.

The results of prototyping and testing showed that the effect of the increased weight of the rotating shaft on the flying distance in actual fishing with a mid-size reel was infinitesimally small.

Compared to the same 42/52 series products that use aluminum shafts, this product was selected for its tougher finish.

A magnetic brake system is used as the braking system.

Because it is a non-contact type, it is extremely less affected by humidity and weather than a centrifugal brake, allowing for stable and comfortable casting.

Additional magnets (sold separately) can be installed to further enhance braking effectiveness.

Attention

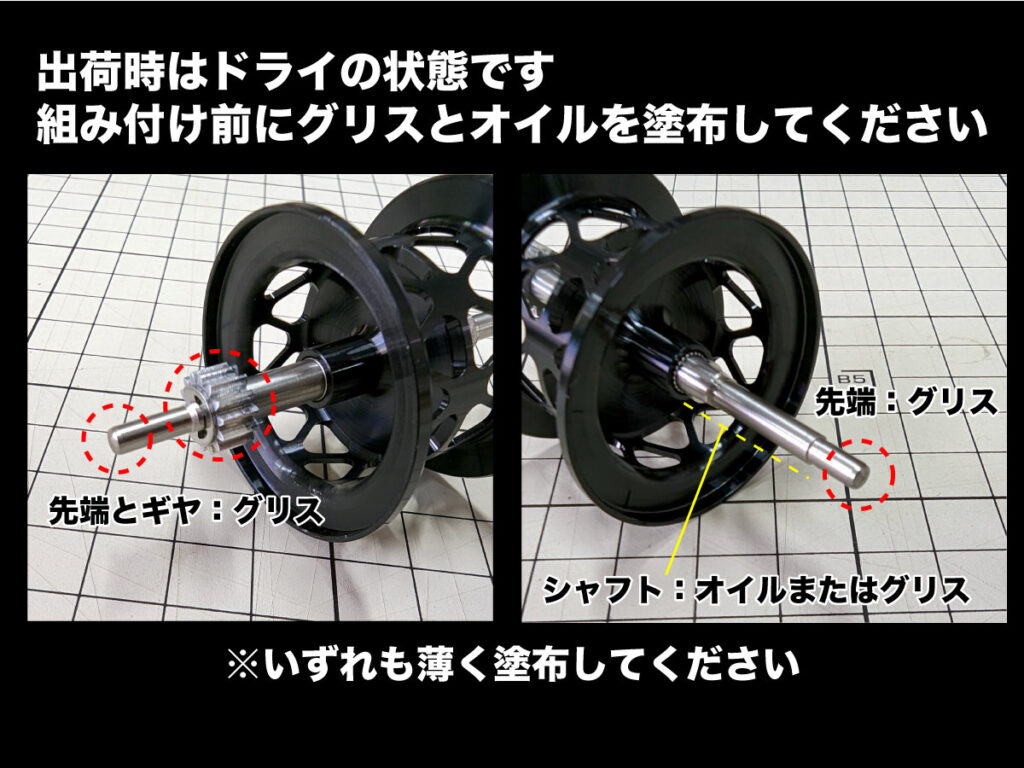

The spool is dry at the time of purchase.

Please apply oil and grease before use.

How to install (BC42 series, BC52 series)

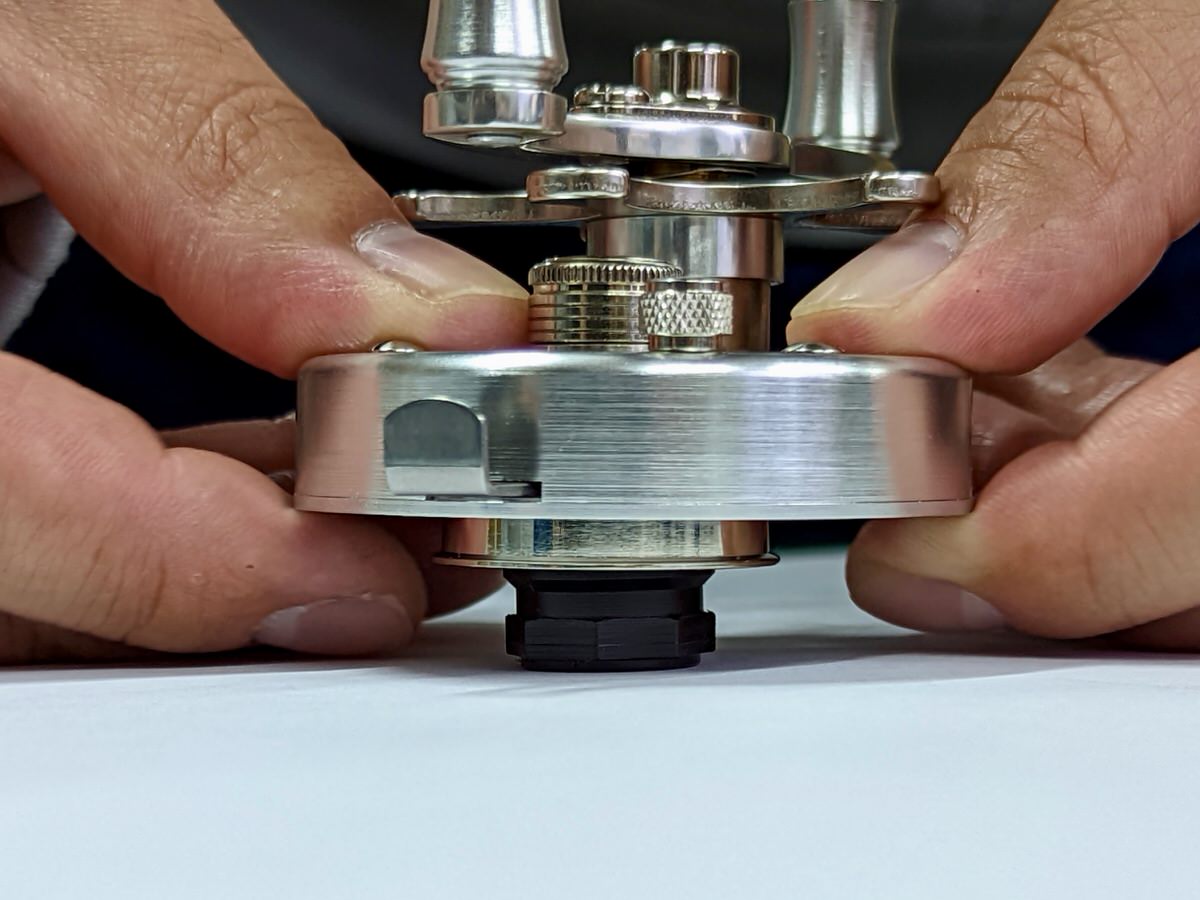

(1) Loosen and remove the 3 retaining screws from the handle side unit.

(2) Insert the 4: spacer into the bearing case on the handle side unit with the side with the larger inner diameter toward the back, up to the base of the bearing case.

Place the product so that this side is on the far side.

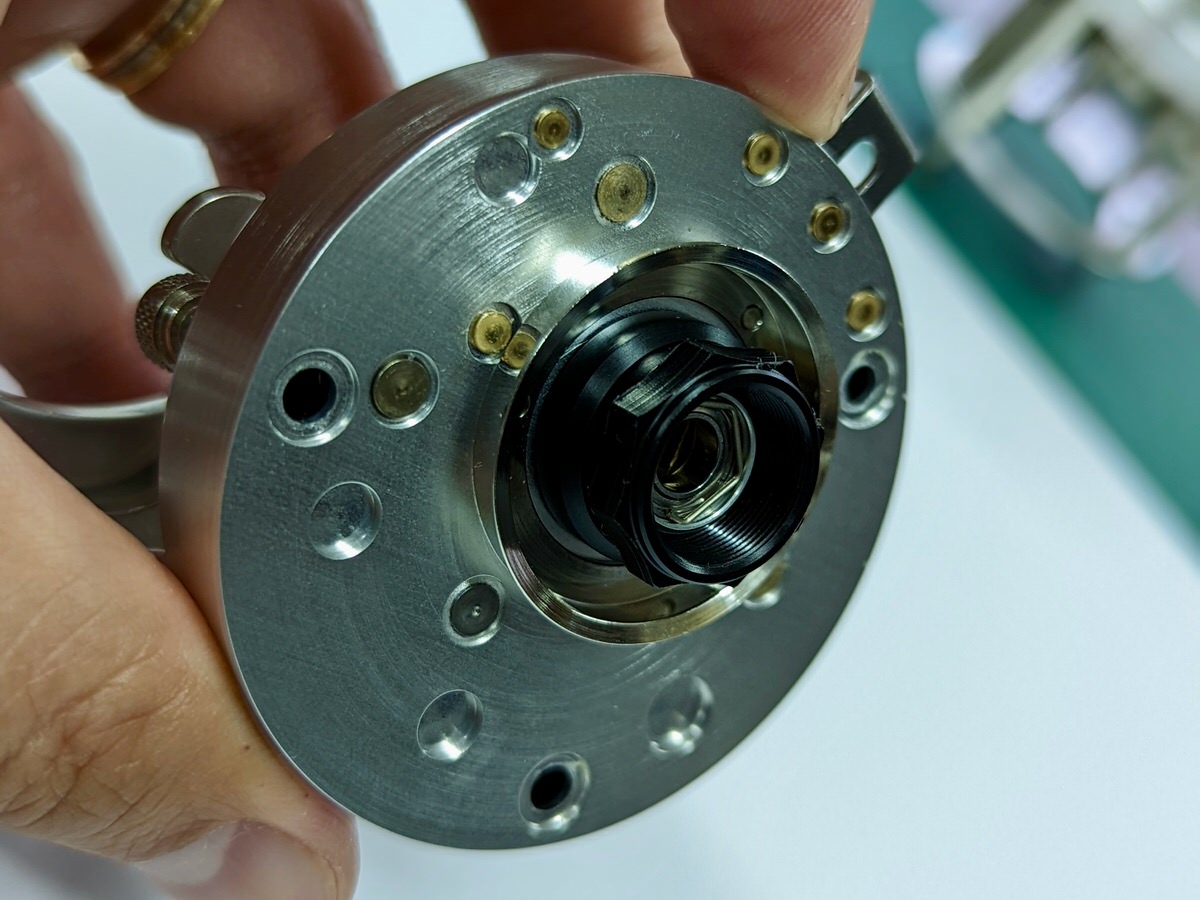

(3) 5: Fit the O-ring.

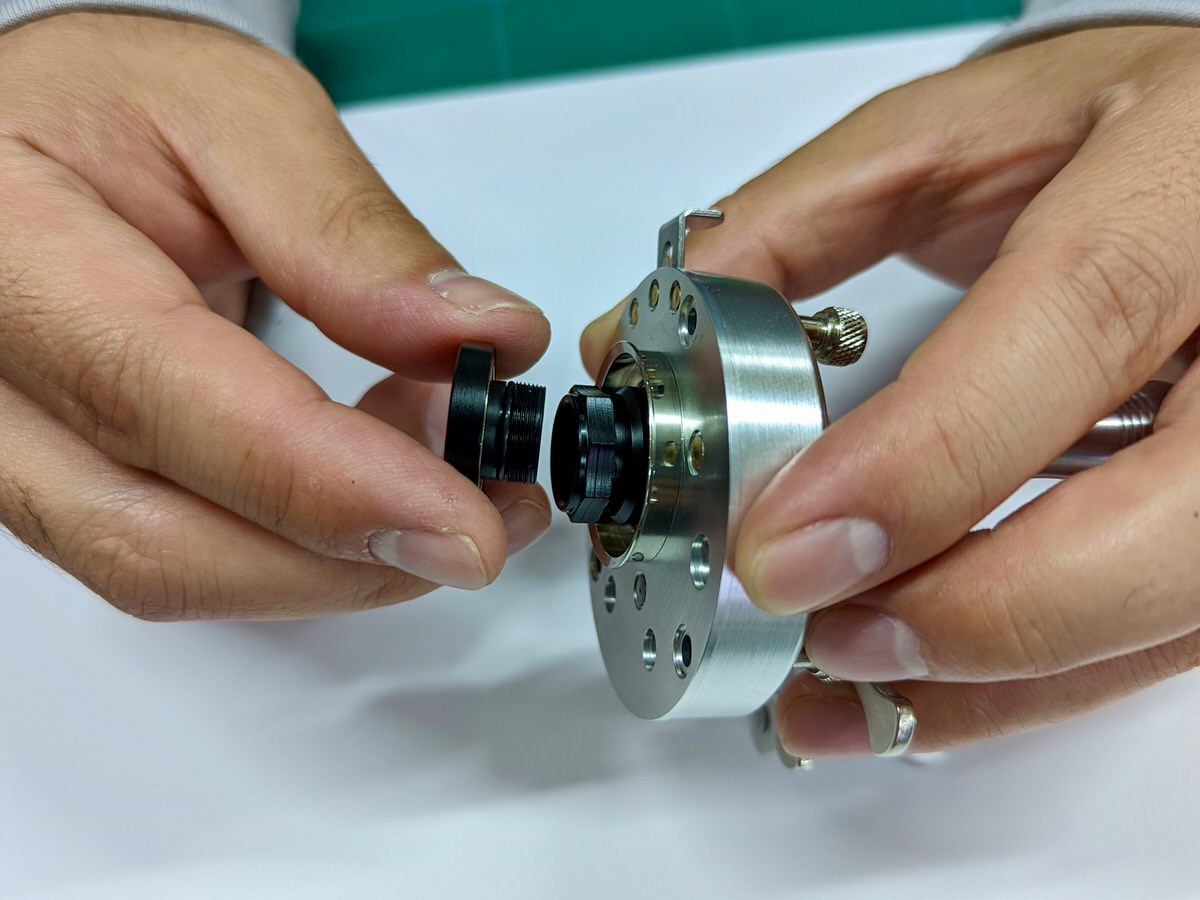

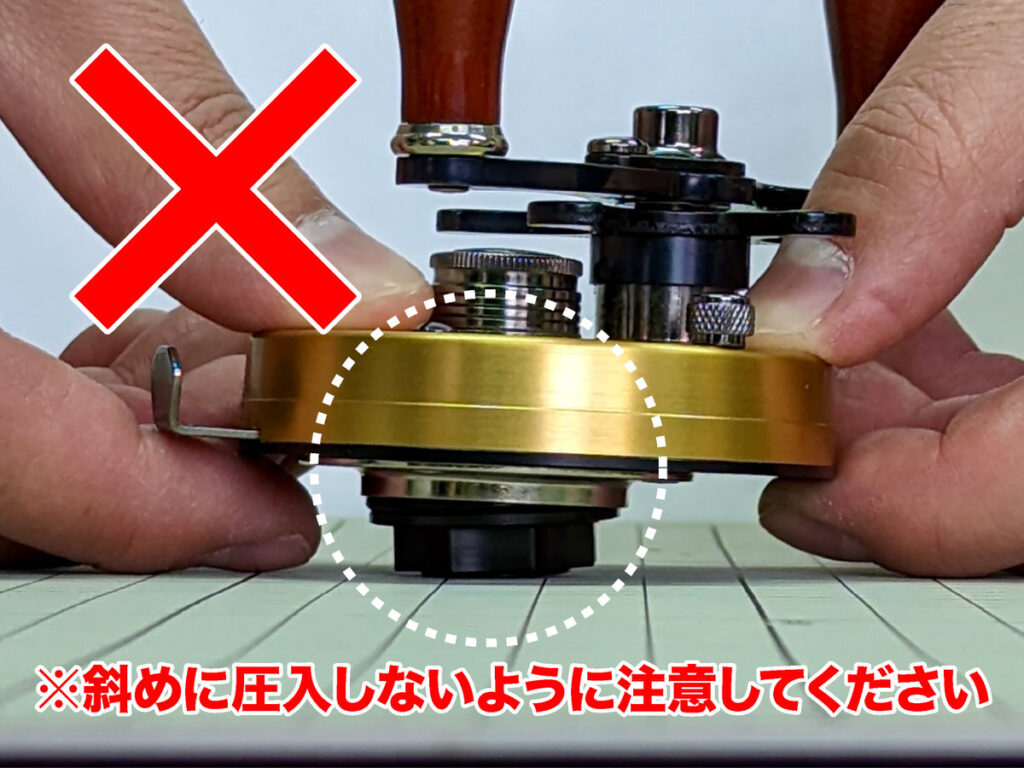

(4) 2: Press-fit the bracket to the face position of the bearing case so that it fits snugly.

Place the 2: bracket on a table or other hard flat surface and press the handle side unit straight down from above.

It can also be attached using fingers. Press straight down from above. Please be careful not to damage your fingertips.

Pressing at an angle may cause malfunction or inoperability.

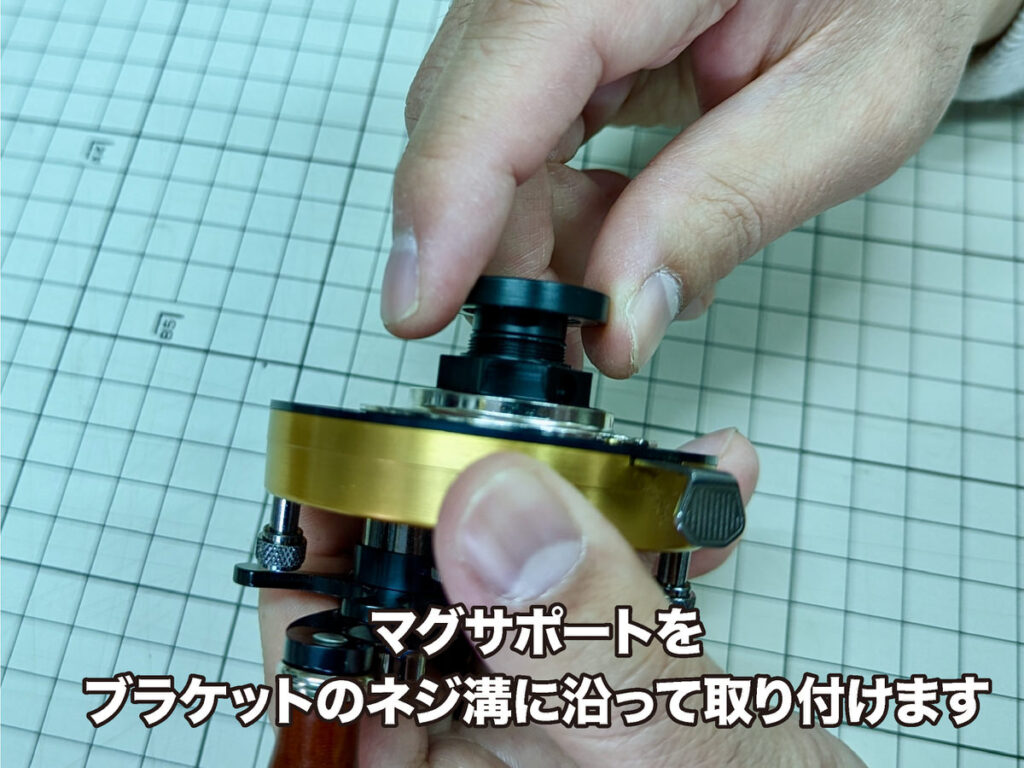

(5) Install the 3: mag support assembly while aligning it with the screw groove of the 2: bracket and tightening it.

Installation is complete.

How to adjust the mag brake

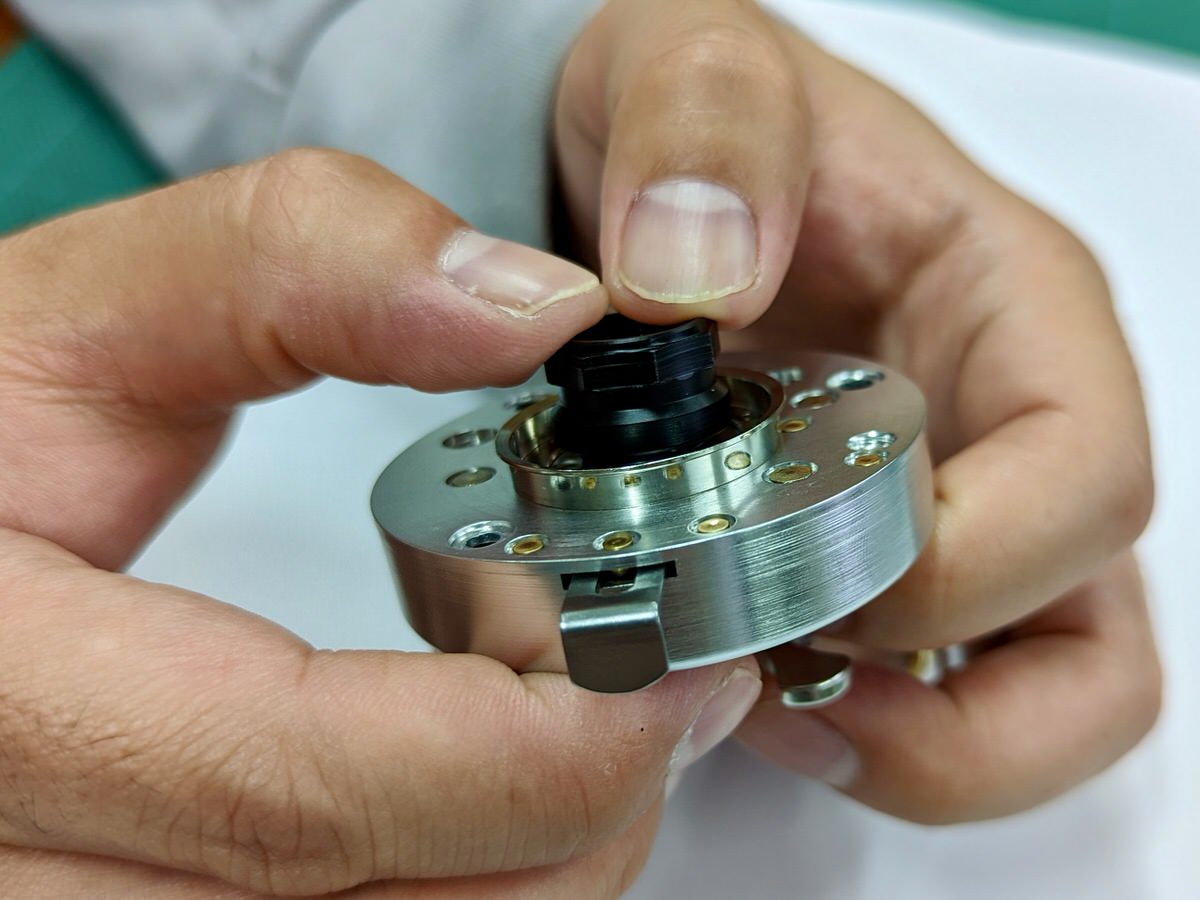

(1) 1: Install the Tough Light spool.

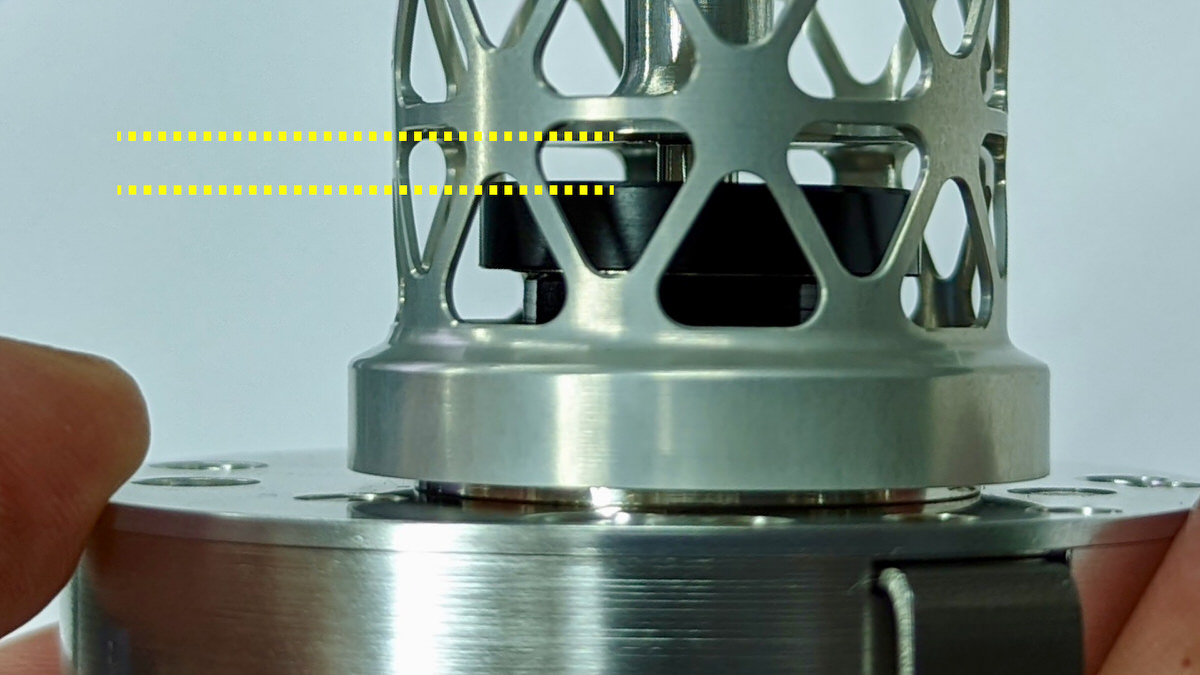

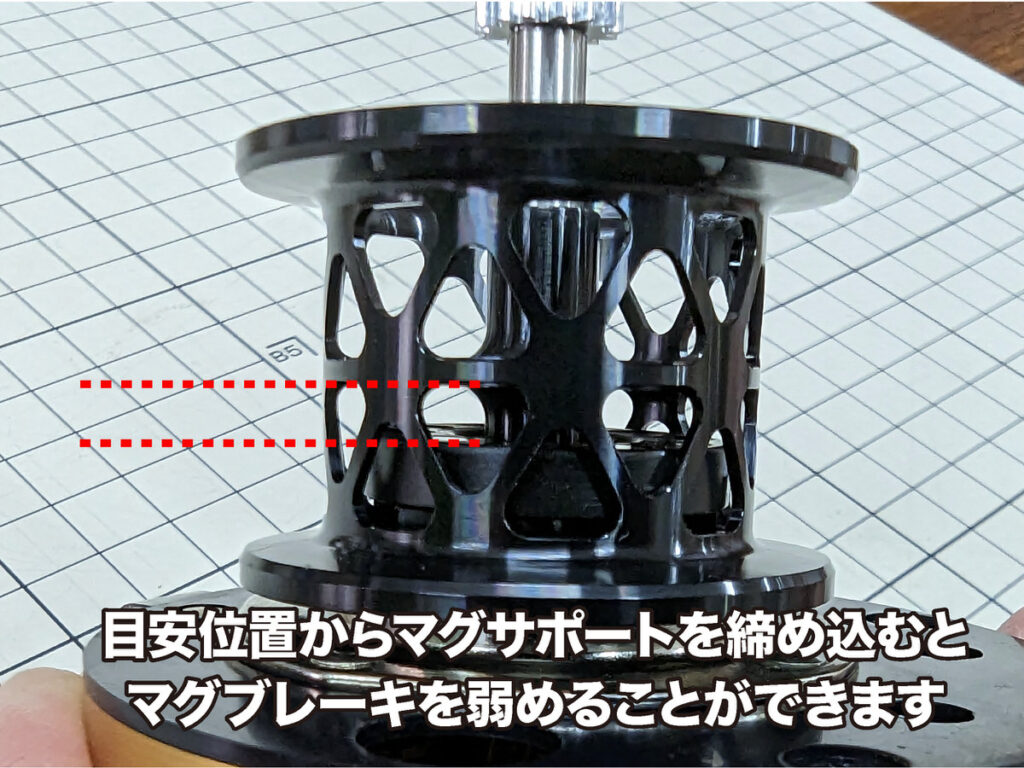

(2) The standard position of the mag brake is at about 0.5 mm gap from the spool surface.

(3) The mag brake can be weakened by tightening the 3:mag support assembly from the reference position.

(4) Install the handle side unit and tighten the let screw to complete the installation. Test the cast and readjust the strength of the mag brake if necessary.

How to install (BC62/73 series, BC72 series)

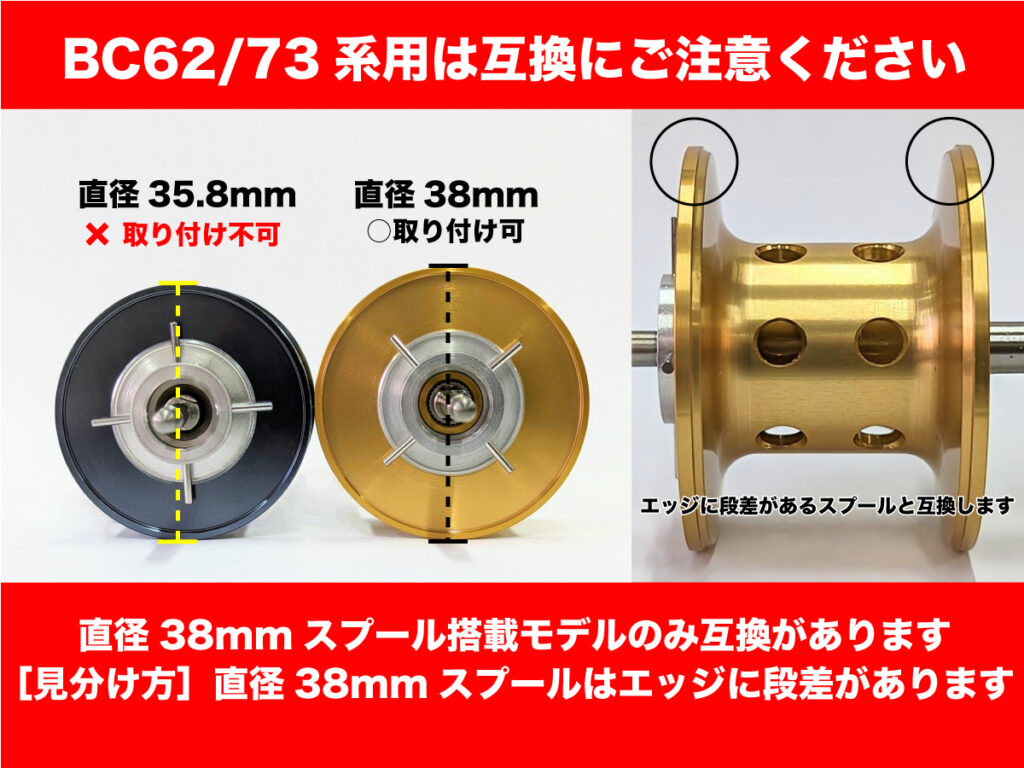

* Please note compatibility for BC62/73 series.

* Only models with 38mm diameter spools are compatible.

* [Discrimination] 38mm diameter spool has stepped edges.

Shipment is in dry condition.

Apply grease and oil before assembly.

Apply a thin layer of any of the above.

Loosen the three let screws and remove the handle side unit and spool.

Install the bracket on the inside of the brake drum.

* Resistance is provided due to the O-ring.

Use a flat surface to press-fit the bracket straight.

* Be careful not to press-fit at an angle.

Install the mag support along the threaded groove of the bracket.

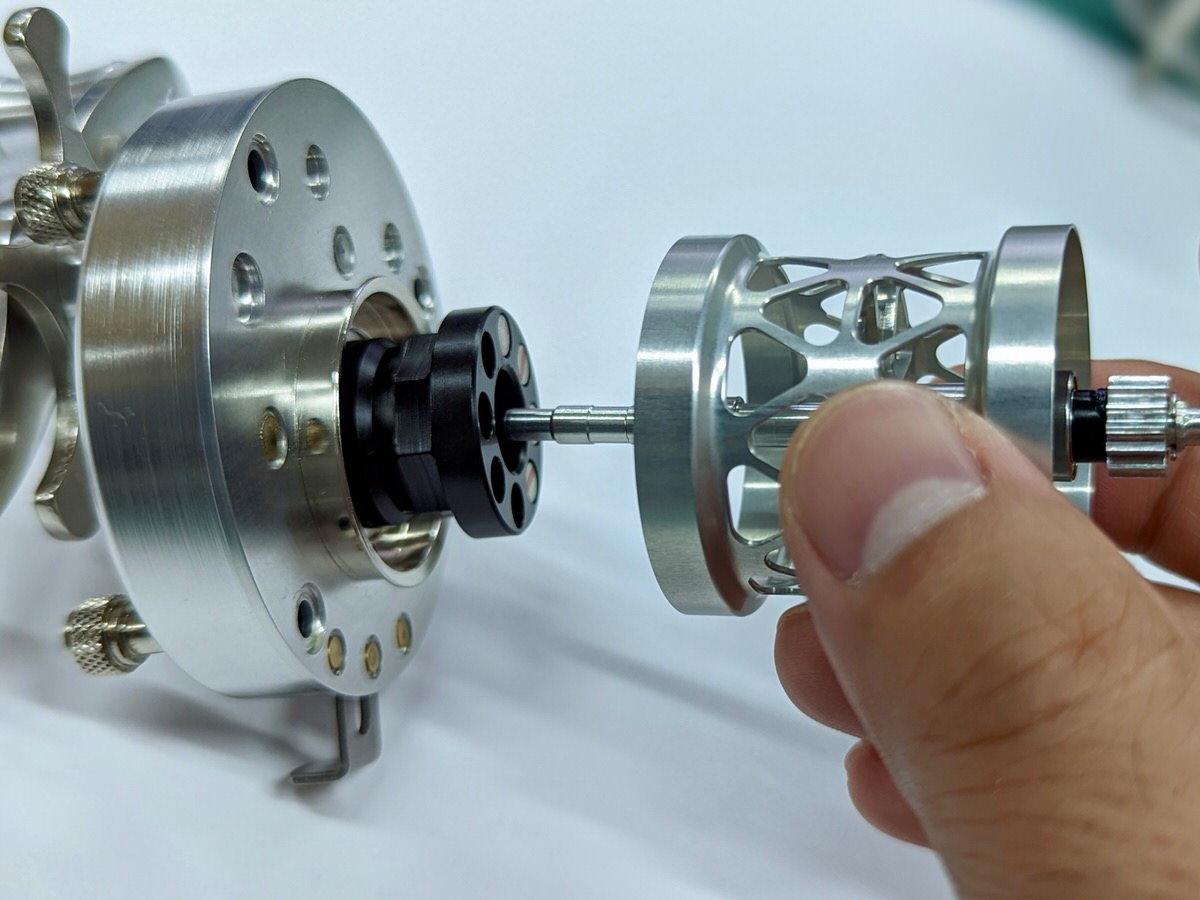

Install the Tough Light spool.

The recommended position for the max (strong) mag brake is about 0.5 mm gap width.

Be careful not to allow the surfaces to contact each other.

Adjust the gap between the spool surface and the mag support surface.

Tightening the mag support from the reference position weakens the mag brake.

Press the push button and turn the spool by hand to check rotation.

Insert the spool into the body side.

Then install the handle side unit.

Completed.

Do a cast test and adjust the brake effectiveness.

The photo shows BC620SSS. The installation procedure for the BC72 series is similar.

CHECK

- Please note that if the mag support contacts the spool surface, rotation failure will occur.

- By pressing the push button and turning the tuff light spool by hand, you can check the effectiveness of the mag brake by the convergence of the rotation.

When the Mag Support and Bracket are fixed

If the mag support is tightened off, it may be fixed to the bracket.

If the mag support and bracket cannot be rotated together for positioning, loosen them as follows.

2: Fix the curved groove in the octagonal part of the bracket's outer circumference with a coin or other edge to hold it from turning.

You will only be able to turn mag support.

If the bracket and mag support cannot be loosened by the above method, remove the bracket and mag support together, loosen them, and reassemble them.

In this case, the spacer and o-ring may come out with the bracket hole.

Be sure to remove the unit before installing it according to the assembly sequence.

Removing and adding magnets

The magnets should be incorporated on the front side with N-pole-S-pole alternately.

The N-pole is marked in red.

Magnets are adsorbed by applying a steel mag stopper on the back side of the mag support.

When removing the magnets, please remove them by adsorbing the magnets on a flat surface such as a screwdriver.

Remove all magnets to remove the mag stopper.

If you want to make the mag brake even more effective, please purchase a magnet (sold separately).

Up to 4 additional pieces can be added.

Handling of magnets

Please be especially careful that small children do not accidentally ingest the product.

Proximity to electronic medical devices such as cardiac pacemakers may impair their normal operation.

Placing the product close to precision instruments such as PCs, smartphones, watches, etc. may cause malfunctions.

If you place a credit card, cash card, etc. near the device, it may not be able to be used.

We are not responsible for any injury or loss caused by handling.

Compatibility

(for BC42 series)

- ISUZU Industry Inc.

BC420/421SSS

BC420/421SSSC

BC431SSS

- Jointer special order color model

BC421SSS

- ISUZU Industry Inc. x TRY-ANGLE collaboration model

BC420SSS-T

BC420/421SSS-T2

BC420/421SSSC-T3

BC431SSS-T,T2

(for BC52 series)

- ISUZU Industry Inc.

BC520/521SSS

BC520/521X

BC521ABC

- Jointer special order color model

BC521SSS

- ISUZU Industry Inc. x TRY-ANGLE collaboration model

BC521SSS-T

BC520/521X-T

- ISUZU Industry Inc. x Fishman x TRY-ANGLE collaboration model

BC520/521X-TF

(for BC62/73 series)

- ISUZU Industry Inc.

BC620/621SSS * Spool diameter 38 mm

BC730/731SSS

- ISUZU Industry Inc. x TRY-ANGLE collaboration model

BC620/621SSS-T

(for BC72 series)

- ISUZU Industry Inc.

BC720/721SSS

(for DD31 series)

- ISUZU Industry Inc.

DD310/311SSS

Other compatible models

(for BC42 series)

- SMITH

Plugger LH/RH

- HeadHunters

HEAD HUNTER SPORTS

PYRAMID-HEAD

- Tsunami LURES × HeadHunters

Sonicmaster Alternative AT-2600

- STOCK LURES

WarinStar

WarinSoul W

(for BC52 series)

- SMITH

SMITH 50th Anniversary Super Strike Reel

- Brightliver

FO-43A/B

- HeadHunters

DELTA 6

- STOCK LURES

WarinSoul

- Megabass

Pagani P300/P300L

- FROG

TOY-MACHINE SUPERLATIVE

Please note

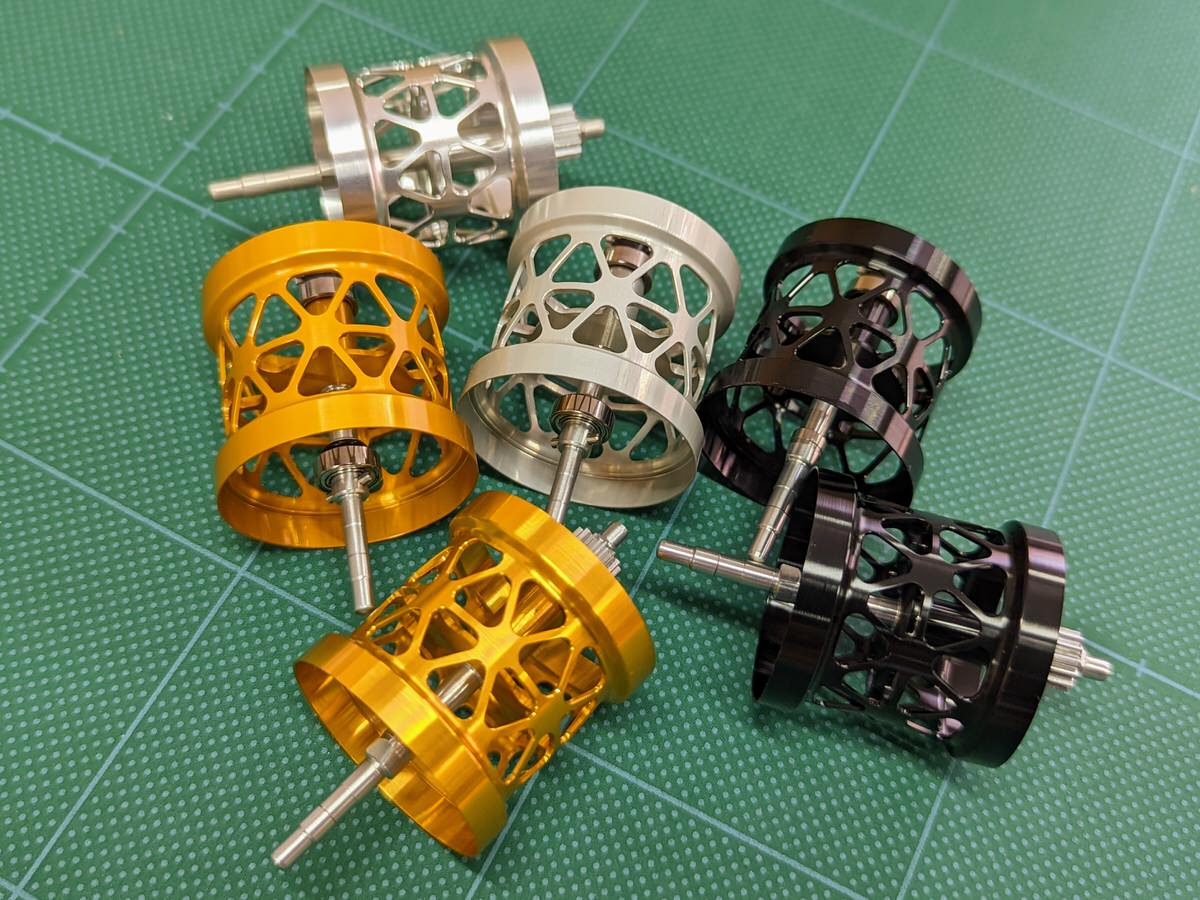

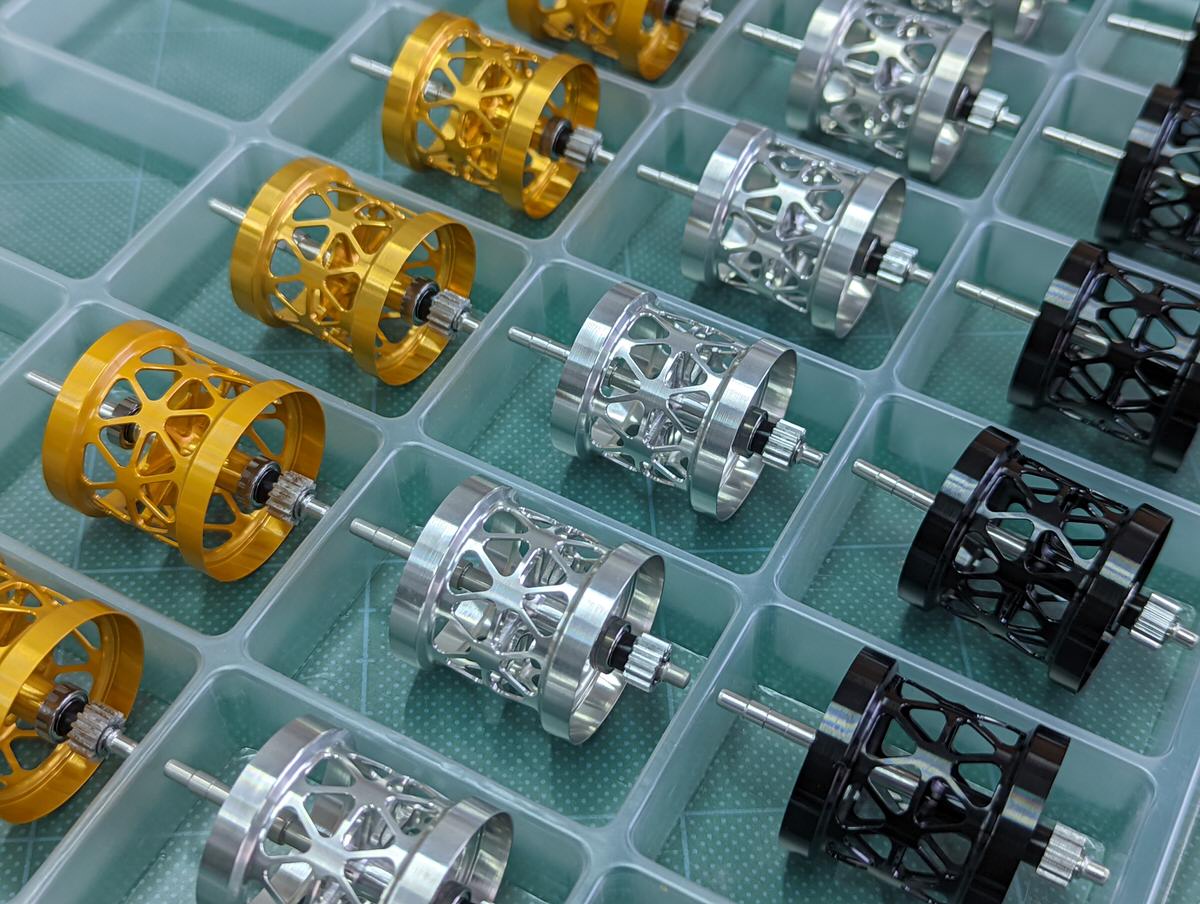

Due to the special shape and robustness of the aluminum alloy used in this product, there are individual differences in color.

Even within the same product, there may be differences in color loss and color tone depending on the angle and the way the product is viewed.

Due to the manufacturing process, there may be minute processing marks or scratches. All of them are safe for use.

Spec

Composition: Tufflite spool bracket Mag support set (with 4 magnets, mag stopper and O-ring) Spacer O-ring

for BC42 series

Spool weight: approx. 8.2 g

Nylon Line Capacity *

4lb - 80 m

6lb - 55 m

8lb - 40 m

for BC52 series

Spool weight: approx. 9.2 g

Nylon Line Capacity *

4lb - 80 m

6lb - 55 m

8lb - 40 m

for BC62/73 series

Spool weight: approx. 16.3 g

8lb - 150 m

10lb - 120 m

12lb - 100 m

for BC72 series

Spool weight: approx. 18 g

8lb - 190 m

10lb - 155 m

12lb - 130 m

for DD31 series

Spool weight: approx. 8.2 g

4lb - 80 m

6lb - 55 m

8lb - 40 m

* Line Capacity varies depending on the line and the tension of the reel. The indicated amount of thread should be used as a guide.

The indicated yarn spools are to be used as a guide only.

Installation Video

→ Explanation of Assembly Method

→ Trouble Shooting

Source: TRYALL inc.

![Photo1: [TRY-ANGLE] Tough Light Spool & Mag Brake System Set (1)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303232303931325f6461666564332e6a706700363030000074006669745f686569676874.jpg)

![Photo2: [TRY-ANGLE] Tough Light Spool & Mag Brake System Set (2)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303232303931325f3332313337382e6a706700363030000074006669745f686569676874.jpg)

![Photo3: [TRY-ANGLE] Tough Light Spool & Mag Brake System Set (3)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303232303931325f6431303531382e6a706700363030000074006669745f686569676874.jpg)

![Photo1: [TRY-ANGLE] Tough Light Spool & Mag Brake System Set (1)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303232303931325f6461666564332e6a706700313130000074006669745f686569676874.jpg)

![Photo2: [TRY-ANGLE] Tough Light Spool & Mag Brake System Set (2)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303232303931325f3332313337382e6a706700313130000074006669745f686569676874.jpg)

![Photo3: [TRY-ANGLE] Tough Light Spool & Mag Brake System Set (3)](https://www.hedgehog-studio.co.jp/phone/data/hedgehog-studio/_/70726f647563742f32303232303931325f6431303531382e6a706700313130000074006669745f686569676874.jpg)